Pharmaceutical Building Design & Construction Services: Creating Compliant and Future-Ready Facilities

Introduction

Pharmaceutical facilities are more than just buildings—they are highly specialized environments that require precise planning, innovative design, and strict compliance with global standards. With the pharmaceutical industry expanding rapidly, businesses need professional pharmaceutical building design & construction services to stay competitive, meet regulatory requirements, and enhance operational efficiency.

From manufacturing plants to research and development labs, the design and construction of these facilities must integrate advanced technologies, cleanroom systems, and environmental controls. Whether you are building a new facility or upgrading an existing one, professional services ensure compliance with GMP (Good Manufacturing Practices), ISO 14644, and other regulatory guidelines.

What Are Pharmaceutical Building Design & Construction Services?

Overview of Services Offered

Pharmaceutical building design and construction services encompass every aspect of creating a compliant and efficient facility, including:

- Site selection and layout planning.

- Cleanroom design and contamination control systems.

- HVAC systems for temperature, humidity, and airflow management.

- Compliance with ISO, GMP, FDA, and WHO standards.

Importance of GMP-Compliance in Pharmaceutical Facilities

GMP guidelines ensure that pharmaceutical products are consistently produced and controlled according to quality standards. Designing facilities that adhere to these guidelines minimizes contamination risks and ensures product safety.

Key Components of Pharmaceutical Building Design

Layout Planning for Efficiency

An optimized layout minimizes movement of materials and personnel, reducing contamination risks and improving operational efficiency.

Cleanroom Integration for Contamination Control

Cleanrooms are critical for sterile manufacturing processes. Proper design ensures that contamination risks are minimized through air filtration, pressure control, and seamless finishes.

HVAC Systems and Environmental Controls

Advanced HVAC systems regulate temperature, humidity, and airflow, maintaining ideal conditions for pharmaceutical production and storage.

Industries Relying on Pharmaceutical Buildings

Pharmaceutical Manufacturing

Facilities are designed to support sterile production lines, packaging, and quality control processes.

Research and Development Facilities

These facilities require precision-designed labs and controlled environments for drug discovery and testing.

Biotechnology and Vaccine Production

Specialized areas are designed to support complex processes like cell culture, aseptic filling, and storage of sensitive materials.

Compliance and Standards in Pharmaceutical Facilities

ISO 14644 for Cleanrooms

ISO 14644 outlines classifications for cleanrooms based on the number of airborne particles. Adhering to these standards ensures global compliance.

GMP Guidelines for Pharmaceuticals

GMP compliance ensures the quality, safety, and efficacy of pharmaceutical products by minimizing risks like cross-contamination and errors.

WHO and FDA Regulations

Global standards, such as those set by the World Health Organization (WHO) and the US Food and Drug Administration (FDA), are critical for exporting pharmaceutical products.

Pharmaceutical Building Design Process

Initial Consultation and Site Analysis

The process begins with understanding the client’s requirements, evaluating the site, and ensuring feasibility for pharmaceutical operations.

Conceptual and Detailed Architectural Design

Architects develop layouts that maximize efficiency while adhering to GMP and ISO standards.

Project Management and Construction

Experienced construction teams bring the designs to life, ensuring timelines, budgets, and quality standards are met.

Cleanroom Design in Pharmaceutical Buildings

Importance of Cleanrooms for Sterile Manufacturing

Cleanrooms maintain controlled environments that are essential for sterile production processes, ensuring compliance and product safety.

Modular Cleanroom Systems

Modular cleanrooms offer flexibility, scalability, and faster construction timelines compared to traditional systems.

HVAC and Environmental Control Systems

Temperature, Humidity, and Airflow Regulation

Precise control of environmental factors ensures ideal conditions for manufacturing and storage.

Role of HEPA and ULPA Filtration Systems

High-Efficiency Particulate Air (HEPA) and Ultra-Low Particulate Air (ULPA) filters remove airborne contaminants to maintain cleanroom standards.

Sustainability in Pharmaceutical Facility Design

Energy-Efficient Building Systems

Sustainable HVAC systems, LED lighting, and water-saving technologies reduce operational costs and environmental impact.

Use of Eco-Friendly Materials

Non-toxic, recyclable materials are used to minimize the environmental footprint of pharmaceutical buildings.

Waste Management Systems

Facilities are designed with advanced waste management systems to handle hazardous and non-hazardous waste effectively.

Challenges in Pharmaceutical Building Design & Construction

- Adhering to Strict Compliance Requirements: Meeting GMP, ISO, and other regulations requires specialized expertise.

- Balancing Cost with Quality and Efficiency: Efficient designs help optimize costs without compromising on quality.

- Adapting to Local Climate and Infrastructure: Facilities must be designed to withstand regional environmental conditions.

Benefits of Professional Design & Construction Services

- Ensuring GMP and ISO Compliance: Professional services ensure that facilities meet all regulatory requirements.

- Enhanced Operational Efficiency: Thoughtful designs streamline workflows and reduce risks.

- Long-Term Cost Savings: Sustainable systems and efficient layouts lead to lower operational costs.

Technology Integration in Pharmaceutical Buildings

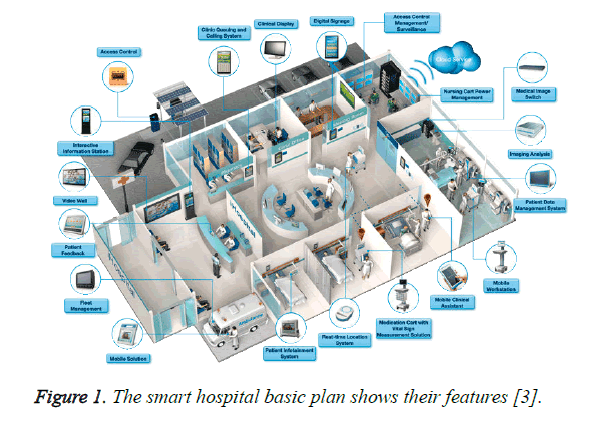

IoT-Enabled Monitoring and Smart Systems

Smart technologies provide real-time data on environmental conditions, ensuring compliance and operational efficiency.

Robotics and Automation in Production Areas

Automation enhances precision and reduces contamination risks in critical manufacturing processes.

Conclusion

Investing in professional pharmaceutical building design & construction services is essential for creating GMP-compliant, efficient, and sustainable facilities. By leveraging expert knowledge, innovative technologies, and regulatory compliance, businesses can build facilities that meet current needs while remaining adaptable to future challenges.

From cleanroom integration to advanced HVAC systems, the design and construction of pharmaceutical facilities is a specialized process that requires a trusted partner. Choose a professional team to ensure your facility achieves global standards and delivers long-term success.

FAQs

What is the importance of GMP compliance in pharmaceutical buildings?

How are cleanrooms integrated into pharmaceutical building designs?

What are the key challenges in designing pharmaceutical facilities?

What technologies are used in modern pharmaceutical buildings?

How does sustainability factor into pharmaceutical facility construction?

Why should I hire professional services for pharmaceutical building projects?

Inbound Link Suggestions:

- “GMP Compliance for Pharmaceutical Facilities”

- “Benefits of Cleanroom Construction in Pharmaceutical Manufacturing”

Outbound Link Suggestions: